Recently, Professor Tian Ming, Professor Cao Pengfei and Associate Professor Yu Bing have published a paper titled “Semi-Interpenetrating Polyurethane Network with Fatigue Elimination and Upcycled Mechanical Performance” on Macromolecules.

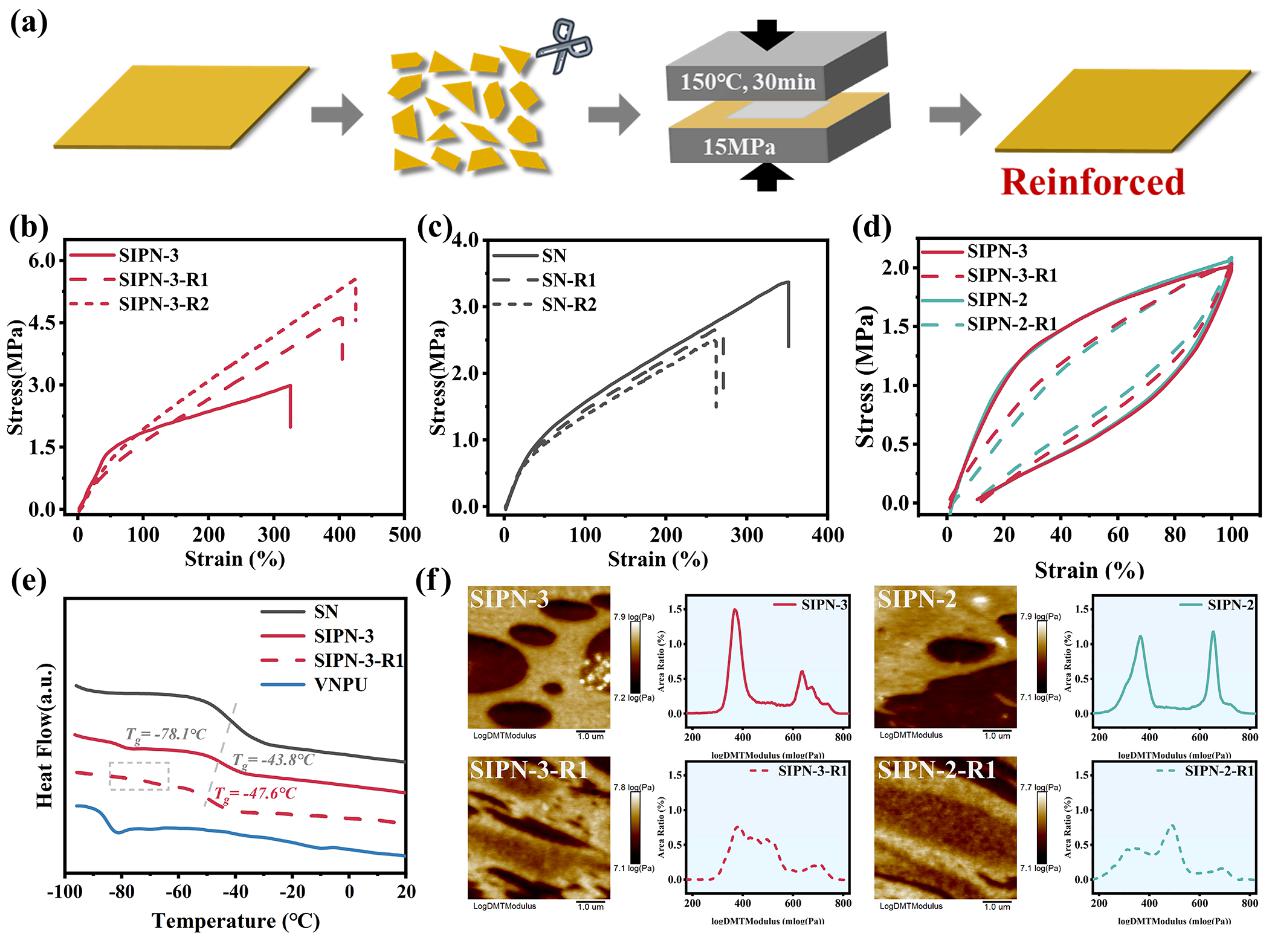

Elastic polymers, which exhibit outstanding flexibility and remarkable elasticity, are extensively employed in fields such as electronic devices, the automotive industry and medical implants. Recyclable elastomers based on adaptable covalent networks fabricated via different types of dynamic bonds have been designed and prepared to resolve the urgent problems generated by waste elastomers. However, due to inevitable side reactions during thermal recycling (e.g., oxidation, permanent crosslinking), mechanical recovery efficiency after thermal recycling is normally <90% for most recyclable elastomers, making it difficult to achieve comparable performance. In this paper, the authors reported a novel semi-interpenetrating network design that achieves mechanical reinforcement after thermal recycling via network topology isomerization and formation of new crosslinking points. The tensile strength and extensibility recycling efficiencies reached 186% and 131% of original values after reprocessing twice, realizing mechanical reinforcement after thermal recycling. Interestingly, based on a similar mechanism, mechanical fatigue after repeated stretch and release cycles was efficiently eliminated upon thermal treatment. Such a strategy achieving polymer design with reinforced physical properties after recycling will benefit practical applications of sustainable elastomers and other thermosetting materials.

https://doi.org/10.1021/acs.macromol.4c00389