Recently, Prof Jichuan Zhang has published a paper titled “Modulus self-recovery phenomenon after shearing of natural rubber based on supramolecular network aggregation structure” on Industrial Crops and Products (Ind. Crop. Prod., 2023, 204, 117302).

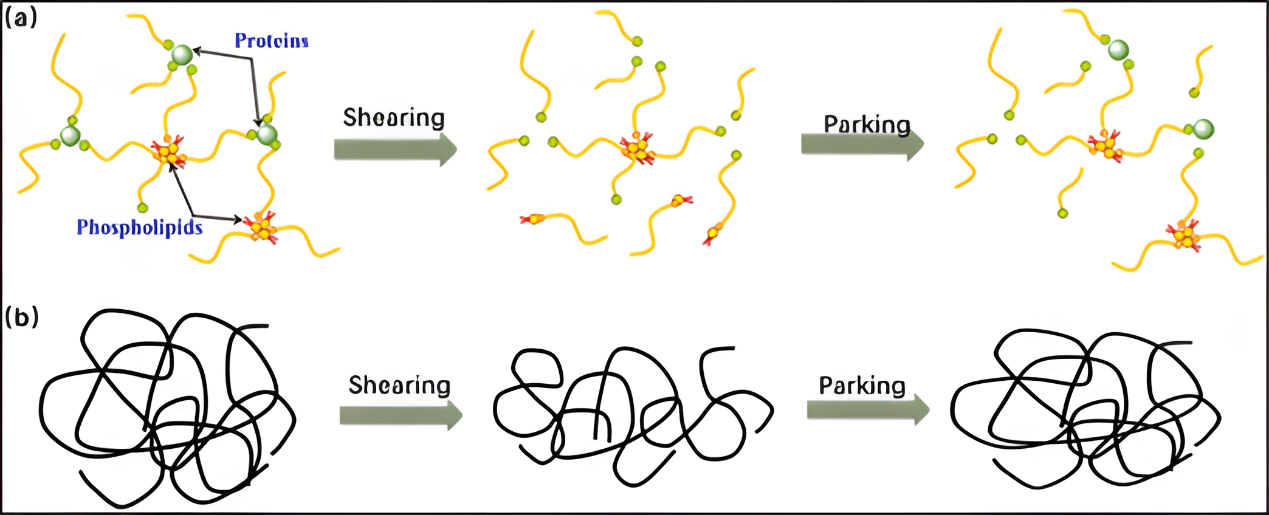

Natural rubber (NR) and isoprene rubber (IR) exhibit a similar shear-thinning phenomenon, in which NR has the inverse ‘S′ shape stress-strain curve and IR has the yield stress-strain curve. Different from IR, NR exhibits the modulus self-recovery phenomenon after shearing. The experimental data showed that the 300% modulus of NR could recover 41.84% after it was sheared 5 times and stored for 30 days. The tensile strength would even recover completely. The modulus self-recovery efficiency (MSRE) would decrease with increasing shearing times. A mechanism model of the structure self-healing efficiency (SSHE) was proposed based on the supramolecular network aggregation structure (SNAS) formed by the weak valence bond of the non-rubber components (NRCs) at the terminal group of the NR macromolecular chains. The mechanical shearing force would break the SNAS of NR and the short molecular chains would fall off from the SNAS. The dropped shorted molecular chains of NR would re-enter the SNAS under the hydrogen-bond interaction generated by the NRCs after storing for a while, increasing the molecular weight and improving the mechanical properties. The 300% modulus would recover partly and the tensile strength might exceed the initial value if the NR was sheared slightly. On the contrary, as the same molecular structure without NRCs, IR did not show any modulus self-recovery phenomenon after shearing. Except it was confirmed by the increased molecular weight and gel content after shearing and storing, this mechanism model could be confirmed by the de-structured transesterification natural rubber (TENR) which did not exhibit the modulus self-recovery phenomenon anymore after removing the NRCs, such as proteins and phospholipids.

https://doi.org/10.1016/j.indcrop.2023.117302